About us

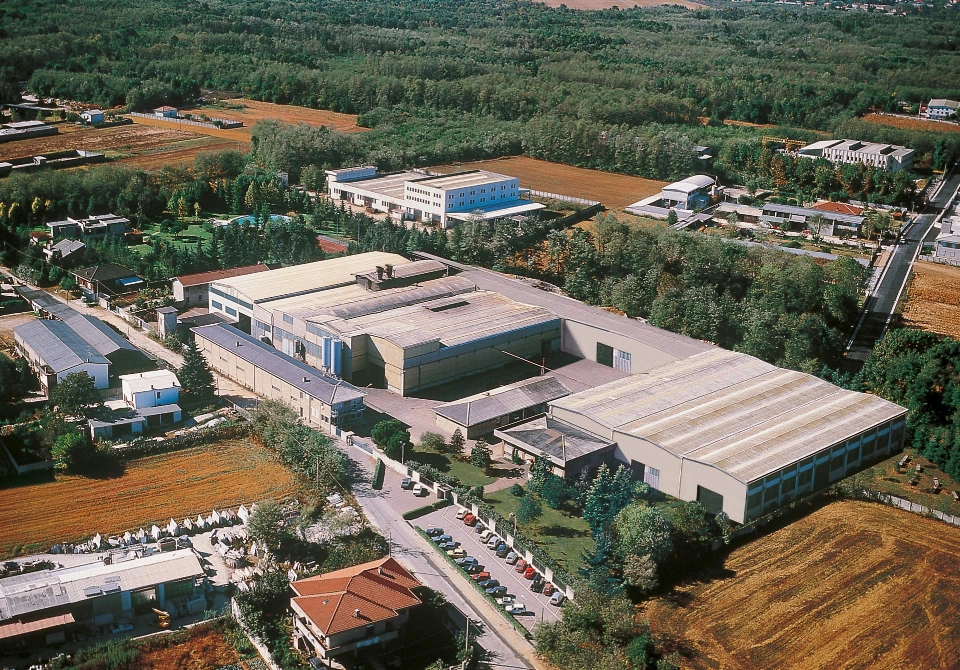

The company G.M.C Srl (Gioria Machines & Components) takes over in November 2022 one of the most important brands internationally in the production of cylindrical grinding machines, known and appreciated for their precision, quality, solidity and reliability, the Gioria Ltd.

The company G.M.C, was founded with the entrepreneurial idea of reviving and implementing the Made in Italy know-how, convinced that technological implementation is the only way to respond to the ever-increasing demands of the market is therefore authoritatively inserted as a primary player in the domestic and international cylindrical grinding machine market.

The company G.M.C, was founded with the entrepreneurial idea of reviving and implementing the Made in Italy know-how, convinced that technological implementation is the only way to respond to the ever-increasing demands of the market is therefore authoritatively inserted as a primary player in the domestic and international cylindrical grinding machine market.

Production program

The production program is extremely broad and includes cylindrical grinding machines for exteriors or exteriors/interiors bothconventional moving-table in hydraulic or CNC versions and CNC moving-table grinding machines true peculiarity and hallmark of

the company.

Available with center distances from 1000 mm to 10 meters, maximum grindable diameter up to 2000 mm and maximum allowable workpiece weight in the machine up to 40 tons, all grinding machines come with a rich set of options.

Careful construction, use of the best materials, and continuous and scrupulous checks during every stage from design to production are a guarantee of high quality and long life of the final product.

Dedicated to the research and development of customized and built-to-measure solutions for the needs of each individual customer, G.M.C. through an experienced team that has been working in the field for decades, assisted now by new talents included within the company is able to ensure the necessary flexibility in order to meet each individual customer request.

G.M.C., offers itself to its customers as a qualified technological partner by providing its expertise to identify the best solution to each grinding requirement.

Dedicated to the research and development of customized and built-to-measure solutions for the needs of each individual customer, G.M.C. through an experienced team that has been working in the field for decades, assisted now by new talents included within the company is able to ensure the necessary flexibility in order to meet each individual customer request.

G.M.C., offers itself to its customers as a qualified technological partner by providing its expertise to identify the best solution to each grinding requirement.

Energy efficiency

GMC S.r.l. corporation considers it a priority to intervene in energy recovery management through environmentally sustainable implementations. All variable speed drives installed on our machines have additional options for optimizing the energy efficiency of the “drive system.”

During braking, energy is produced that is normally dissipated; with our regeneration technology, this energy can be fed into the grid.

With these energy-saving functions of SINAMICS converters, it is possible depending on the application to reduce energy requirements.

During braking, energy is produced that is normally dissipated; with our regeneration technology, this energy can be fed into the grid.

With these energy-saving functions of SINAMICS converters, it is possible depending on the application to reduce energy requirements.

Using SINAMICS converters with Active Line Module reduces the capacitive and/or inductive reactive power of the machine.

In this way, expensive reactive power compensation systems can be saved. During machine operation, current energy consumption can be displayed and by means of the installed energy-saving meter.

In this way, expensive reactive power compensation systems can be saved. During machine operation, current energy consumption can be displayed and by means of the installed energy-saving meter.